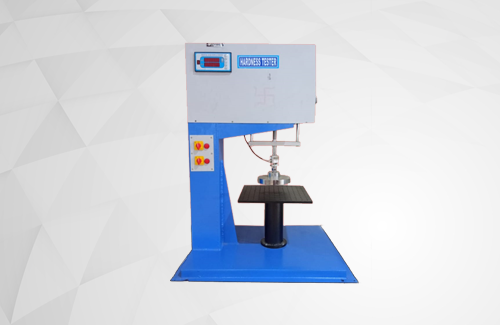

Indentation Hardness Tester

For Testing Coil Springs

Ensuring Durability and Performance through Precision Testing

In today’s advanced manufacturing and material testing landscape, quality assurance has become non-negotiable. Polyurethane foam, a versatile material widely used in furniture, automotive seating, bedding, packaging, and insulation, requires stringent quality control to ensure consistent performance and comfort. One of the most reliable and standardized ways to assess the mechanical properties of polyurethane foam is by using an Indentation Hardness Tester.

Indentation Hardness Tester

What is an Indentation Hardness Tester?

An Indentation Hardness Tester is a specialized testing machine designed to determine the hardness number and load quotient of flexible materials, especially polyurethane foam. The instrument measures the force required to indent the foam to a specified depth, providing a direct indication of its firmness or softness. The test is standardized according to methods like ASTM D3574, ensuring uniformity and reliability of results.

Importance of Hardness Testing in Polyurethane Foam

Hardness testing of polyurethane foam plays a critical role in assessing:

- Comfort Levels: Particularly important in mattresses, cushions, and automotive seats.

- Durability: Ensures the foam retains its shape and firmness over extended use.

- Quality Consistency: Guarantees every batch meets specified standards, reducing product returns and increasing customer satisfaction.

- Compliance: Meets domestic and international quality standards, supporting certifications and export requirements.

Features of PSI Sales’ Indentation Hardness Tester

Our Indentation Hardness Tester for polyurethane foam is engineered with precision and ease of use in mind. Below are some key features that set it apart:

- Rigid Frame Construction: Provides superior stability during testing.

- Digital Load Measurement System: Accurate load measurement ensures precise determination of hardness number and load quotient.

- User-Friendly Interface: Simple operation suitable for technicians at all skill levels.

- Customizable Test Parameters: Ability to adjust indentation speed and load as per different standards.

- Low Maintenance: Robust design minimizes maintenance requirements, providing long-term reliability.

Applications Across Diverse Sectors

- Furniture and Bedding Industry

Manufacturers of mattresses, pillows, and cushions rely on foam hardness testing to ensure products meet comfort and durability expectations. By using our Indentation Hardness Tester, manufacturers can fine-tune foam formulations and improve product quality. - Automotive Industry

In automotive seating, foam hardness directly affects ride comfort and safety. Our testers help OEMs and component suppliers ensure that the polyurethane foam used in car seats meets strict ergonomic and safety standards. - Packaging and Insulation

Foam used in protective packaging and thermal insulation must maintain certain hardness characteristics to provide adequate protection and insulation efficiency. Regular hardness testing minimizes product failures and enhances brand reliability. - Footwear and Sports Equipment

Foams used in shoe soles and sports equipment require specific hardness levels for impact absorption and support. Accurate hardness testing improves performance and user satisfaction. - Research and Development

Educational institutes, research labs, and technical universities use indentation hardness testing for material development and comparative studies. Our machine offers precise and repeatable results, making it a preferred choice for academic and research purposes.

Why Choose PSI Sales’ Indentation Hardness Tester?

- High Precision and Accuracy

Our testers are designed to provide highly accurate and repeatable results, critical for maintaining quality standards in competitive markets. - Compliance with International Standards

Machines are designed to comply with ASTM, ISO, and BIS standards, making them suitable for both domestic and export-oriented manufacturers. - Strong After-Sales Support

We offer Pan India service coverage, including installation, calibration, operator training, and annual maintenance contracts. Our service centers cover major industrial hubs like Delhi, Mumbai, Chennai, Bangalore, Hyderabad, Pune, Ahmedabad, Kolkata, and more. - Customizable Solutions

We understand that each customer may have unique testing requirements. Our engineers can customize load ranges, indentation depths, and software features to perfectly match your needs. - Trusted by Leading Organizations

Our machines are trusted by leading government laboratories, private companies, and educational institutes throughout India. From foam manufacturers to premier universities, customers rely on our machines for quality control and research.

Technical Specifications

- Test Load Capacity: Customizable as per foam density and customer requirements.

- Indentation Depth: Adjustable, with high precision control.

- Load Measurement Accuracy: ±1% of indicated load.

- Control System: Electronic or microprocessor-based control with digital readout.

- Data Storage: USB and PC interface options available.

- Safety Features: Emergency stop, overload protection, and fail-safe electronics.

Advantages of Investing in PSI Sales’ Indentation Hardness Tester

- Enhanced Product Quality: Consistent hardness results lead to better product quality and customer satisfaction.

- Cost Savings: Minimizes product failures and rejects, reducing costs in the long run.

- Brand Reputation: Helps maintain compliance with global standards, boosting brand credibility.

- Market Competitiveness: Ensures your products meet or exceed industry benchmarks, giving you a competitive edge.

- Pan India Service & Support: We ensure prompt installation, training, and after-sales service. Our comprehensive service model is designed to minimize downtime and maximize productivity for your team.

Request a Quote

If you are a government laboratory, private manufacturer, or educational institution, we can provide a tailor-made solution for your polyurethane foam testing needs.